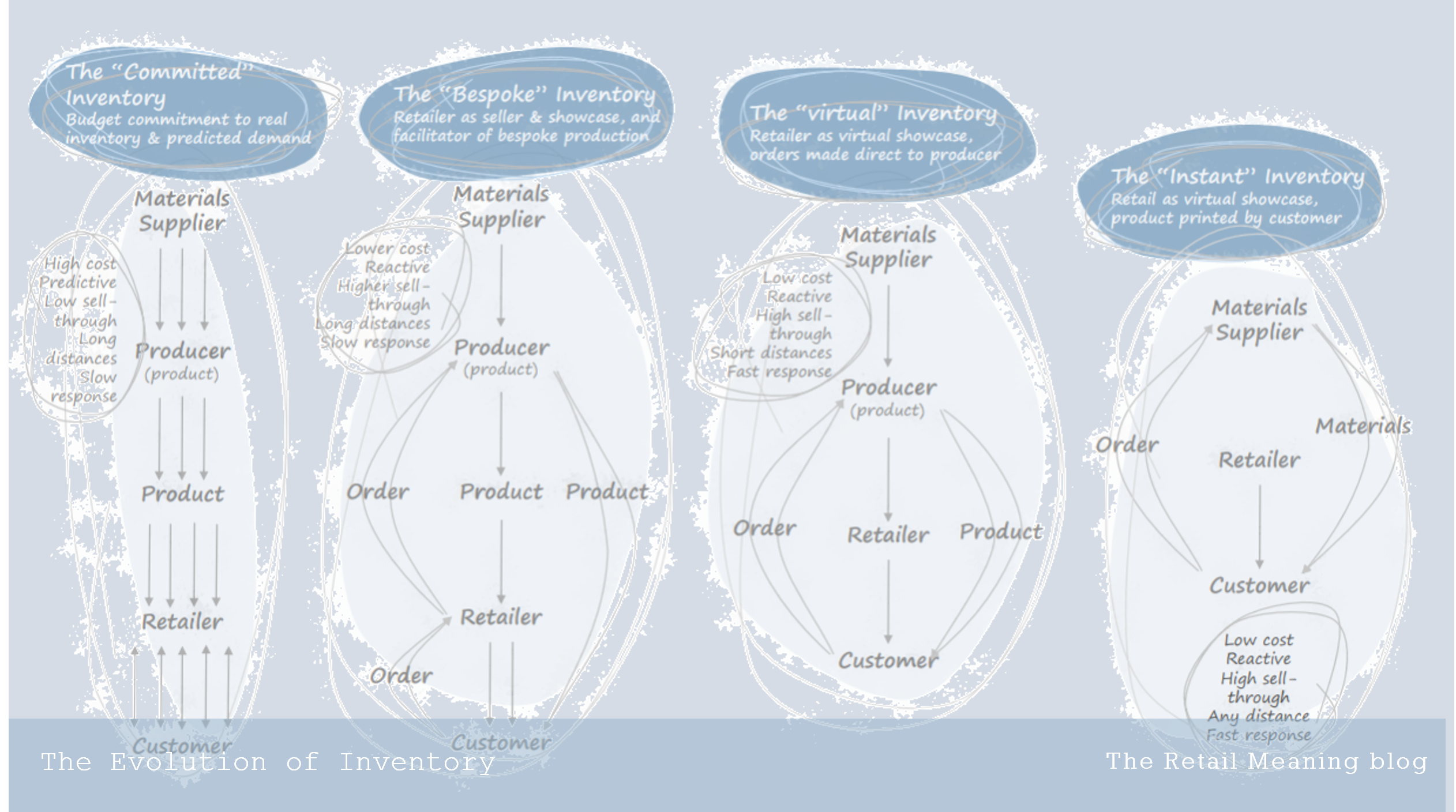

Agile retail businesses are shifting the supply chain to support a major strategic and operational focus on new inventories. The traditional approach of producing an inventory which is then sold, as much as is possible, is being transformed into an approach where a partly, or fully, virtual inventory is showcased as much as possible, and then produced to order.

The enablers of the new processes are built around delaying final commitments to designs, styles, materials, colours and sizes until the latest possible moment. Bespoke inventories use local suppliers and fast response times to refresh and replenish the assortment in shops with the most up-to-date sales data and analysis. Virtual inventories respond

to individual requests and orders from the customer, whilst the advent of instant inventories will potentially put the production of the product directly into the hands of the customer.

‘Right here. Right now.’

The development of non-supplier, supply chains is a dramatic but feasible innovation using 3D printing technology and on demand production technologies.

In essence, this is the ultimate in personalised or bespoke shopping. Only when an order has been received will a collection of raw materials be transformed into the appropriate product, which will then be available in the right place at the right time. That being… right here, right now.

If you are reading this book as a physical product then it will be as a result of POD, ‘print on demand.’ The book exists as a digital file, which springs into action in the hands of a selected few digital printers. The product is produced and shopped within minutes.

Similar technologies are widespread and growing for products such as t-shirts and commodity fashion. Production on demand is no longer just in the market for personalized t-shirts and ‘stag-party’ sweatshirts. It is a tool for mass-production for international brands. Where mass-production can be flexible and responsive. The impact on efficiency, sell-through and as a result commercial profit is equalled by the efficiency in the use of raw materials and the drastic reduction in waste.

POD is one of the most exciting areas of retail and potentially one of the most lucrative for retail businesses who can get their heads, their agile organisations, and their astute strategies around it.

Supplier relationships, and the supply chain, are being transformed from a world of big sheds and slow boats to one of small lead-times and fast technologies.

‘The Evolution of Inventory’ is an extract from the book ‘Meaning in the Retail Madness: How to be an Essential Retailer.’ by Tim Radley.

If you would like to read more about the new ways that retailers are working with suppliers, how to develop different kinds of inventory, the importance of a ‘passion supply chain’ and how supply chains should be determined by product role, then you can find all of this and more in ‘Meaning in the Retail Madness.’