Supply and Demand has always been the driver for commercial brands and retailers. In new and growing markets, the demand temporarily outstrips supply. For those retailers who simply have the means to manufacture and get their product to the marketplace and to the customer, there is a lot of easy money to be made. A lot of easy money has been made.

That was the scenario over recent decades. One of growing populations with more affluent customers. Now that scenario is history. Now supply in most sectors far outstrips demand.

For many business models reducing supply is simply not a commercial viability. Margins and profit is based on volumes. We encounter the scenario where maintaining production volumes, even when more goes to waste, is still more viable, than reducing volumes.

I have witnessed these practices first hand across different sectors. If you have high initial margins and low sustainability values, and commercially it works, then you take the money and run.

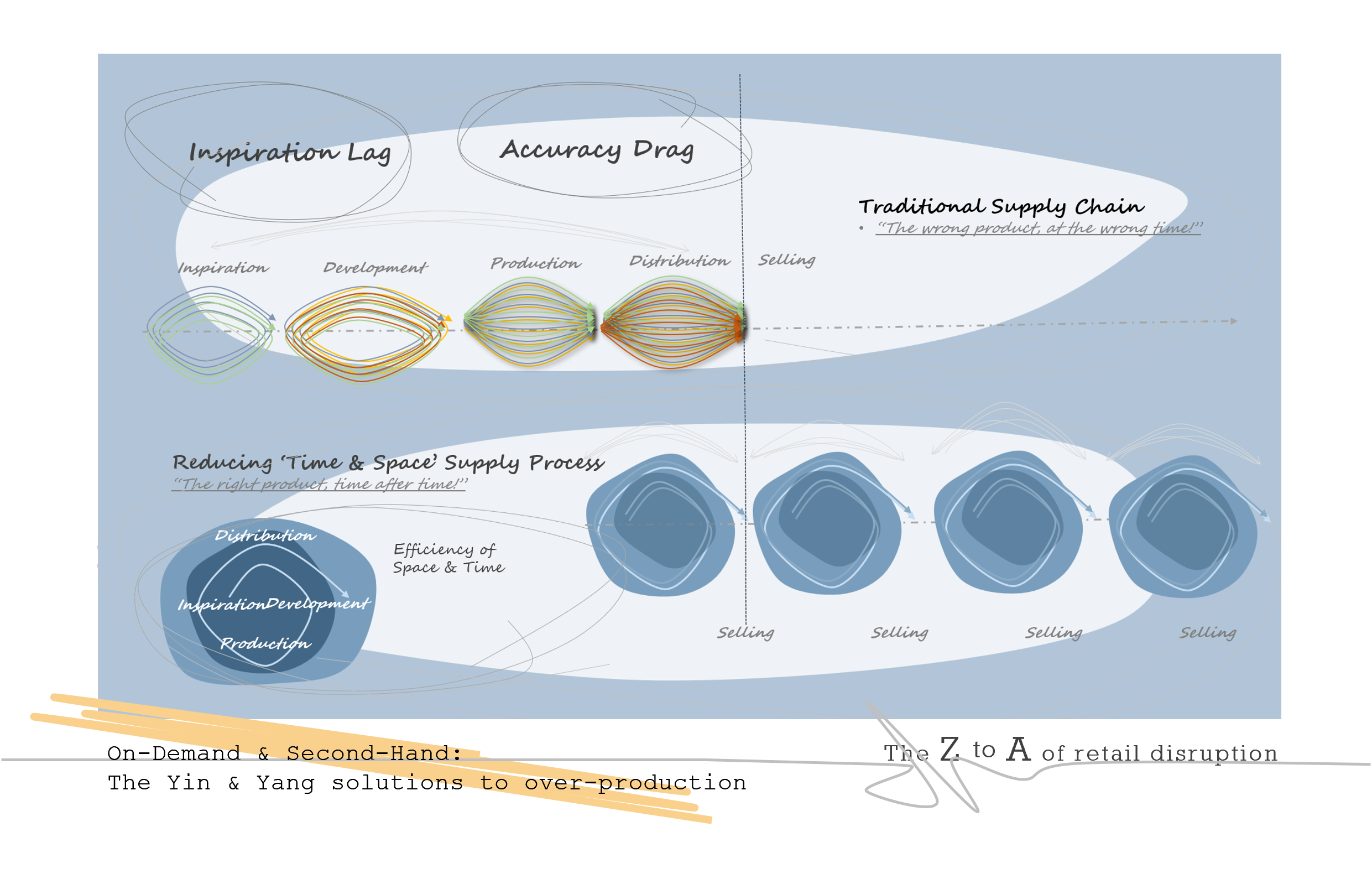

I have also worked with brands who desperately try to modify production volumes to fit the predicted demand. Retailers who at least try to modify assortment structures, category balance, and product styling to reach the buyers panacea of supply=demand.

As with a lot of life’s realities. Supply=demand never happens. And it is an increasingly difficult task for buyers & merchandisers to get even close, in such fluctuating markets. And so, we arrive at the wastelands of overstock.

Thankfully, there are now imaginative entrepreneurial businesses that operate in the excess stock and second-hand markets. Ironically, they survive and flourish from the inefficient over-production and wastefulness of brands.

However, we still have the problem of too much stuff. We still rely on customers to buy things, to buy things, over and over again, to ‘solve’ the problem. The new product pipeline is still open. Markets continue to be flooded with excess.

On-demand turns the supply & demand model on its head. Its fundamental role is to eliminate unwanted product.

Historically, we talk of bespoke, the lengthy process of tailor made clothing and customised furniture. A time when a long production process was a positive, a sign of quality and craftmanship. Fast-forward to an impatient world, where waiting only signals inefficiency, and where product value is perceived through style not substance.

What has changed to make modern On-Demand viable?

Firstly, there is a return to patient consumerism. Where the value of personalisation and customisation is being re-discovered. As an antidote to sameness and monotony, more consumers are accepting, and embracing, the wait for artisans to weave their magic.

Secondly, online assortments offer the opportunity for ‘Virtual Inventories.’ The distance of the digital interface allows products, which do not actually exist yet, to be sold to customers. The key is that new technologies now allow bespoke to be instant.

Customers can now enjoy their customised cake and eat it at modern speeds.

Digital printing of fabrics, and final garments, allows brands to wait for an order, and then move into immediate production and distribution. And now when you think digital printing think of quality as good as traditional fabric processes, think of pattern printing, cutting and skilled assembly in minutes not hours.

Not only is this process fast, but it is also sustainable. Because products are only made when they have been ordered, but because the new technologies use very little water, they also use eco-dyes. And because the production process replaces supply chains that traditionally stretch across the globe.

Times are fast and distances are short.

On-demand is still in its modern infancy but will rapidly grow. And whilst it is not viable for all types of products, On-demand is perfect for the more fashionable product lines, where speed to market is key, and accurate prediction of the ‘look’ is essential.

On-demand brings the point of design, to the point of purchase. Demand is maximised. Demand is in fact guaranteed.

Sustainability in retail will only be achieved through the coordination of different avenues. At its heart is the efficiency of design prediction and supply production, minimising unwanted products. The role of second hand can then be focused on the re-selling of popular products to new owners, not the thankless task of finding resting places for the lost and unloved.